How Increasing Firing Temperature Can Boost Turbine Output – What You Need to Know

In modern power generation, even small efficiency improvements can lead to significant cost savings and output gains. Among the most effective ways to enhance gas turbine performance is through firing temperature increases—raising the temperature at which combustion gases enter the turbine section.

However, pushing this temperature boundary is a delicate balance between performance gains and component longevity. It requires advanced materials, precise cooling systems, and intelligent monitoring to ensure reliability and safety. This article explores how increasing turbine firing temperatures impacts output, the engineering limits involved, and the innovative solutions that make these upgrades possible.

What Is Firing Temperature and Why It Matters

The firing temperature, often referred to as the turbine inlet temperature (TIT), is the temperature of the gases entering the first-stage turbine blades after combustion. This temperature largely determines the specific power output and thermal efficiency of a gas turbine.

In simple terms:

- Higher firing temperatures = higher thermal efficiency.

- Higher efficiency = more power for the same amount of fuel.

Every 10°C increase in turbine inlet temperature can result in roughly a 0.5% to 1% rise in overall efficiency, depending on the turbine model. In large industrial turbines, that gain translates to millions of dollars in fuel savings and additional power generation capacity over time.

But this benefit comes with challenges—especially related to how much heat critical components can endure.

See also: What to Include in a Grant Proposal for a Tech Company

Material Limits: The Key Constraint

Gas turbines operate in some of the most extreme environments in industrial machinery. Combustion gases can exceed 1,500°C (2,732°F), while the melting point of typical metal alloys used in turbine blades is much lower—around 1,300°C (2,372°F).

This means that increasing the firing temperature pushes materials closer to their limits. Without advanced engineering, these components would quickly experience thermal fatigue, oxidation, and creep failure.

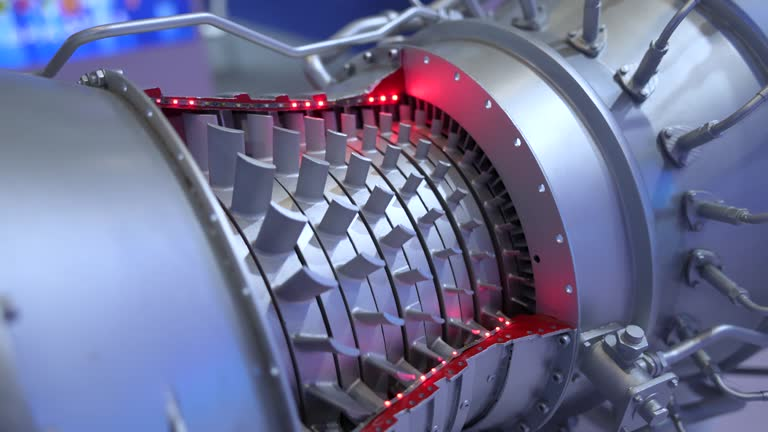

The hot gas path components—including combustion liners, transition pieces, first-stage nozzles, and turbine blades (buckets)—are especially vulnerable. These parts directly face the high-velocity combustion gases and must withstand both intense heat and mechanical stress.

How Cooling Systems Enable Higher Firing Temperatures

To safely raise firing temperatures, gas turbines rely heavily on advanced cooling techniques. These systems ensure that even when gas temperatures climb, the metal surface temperature of critical components remains within safe limits.

1. Film Cooling

Tiny holes in turbine blades allow cooler air to form a thin protective film over the surface. This layer acts as a thermal barrier, shielding metal components from direct exposure to the hot gas stream.

2. Internal Air Cooling

Compressor discharge air is routed through intricate internal channels within the blades and vanes. As the air flows through, it absorbs heat and prevents localized overheating.

3. Impingement Cooling

High-velocity jets of air are directed toward hot surfaces, providing intense, localized cooling in critical areas such as the leading edges of blades.

When properly integrated, these cooling techniques allow turbine manufacturers and maintenance providers like Allied Power Group to safely raise firing temperatures—sometimes by as much as 50–100°C, translating into significant power gains.

Material Upgrades and Coatings for Hot Gas Path Components

Beyond cooling systems, modern material science and coating technologies play a critical role in supporting firing temperature increases.

1. Advanced Superalloys

Nickel-based superalloys are commonly used in turbine blades because they maintain strength and resist creep under extreme heat. Some modern alloys also incorporate cobalt, chromium, or rhenium for added durability.

2. Directionally Solidified and Single Crystal Materials

These materials eliminate grain boundaries in the metal structure, significantly improving resistance to thermal fatigue and creep. They are often used in first-stage turbine blades—the most heat-exposed parts of the machine.

3. Thermal Barrier Coatings (TBCs)

TBCs are ceramic-based coatings applied to metal surfaces. They can reduce the metal surface temperature by up to 200°C, allowing the turbine to operate at higher firing temperatures without damaging the base metal.

Allied Power Group and other advanced service providers use TBC reapplication and repair as part of their hot gas path component refurbishment, ensuring extended service life and consistent performance even after firing temperature upgrades.

The Trade-Offs: What Operators Need to Consider

While firing temperature increases can substantially improve gas turbine performance, they also introduce certain trade-offs that must be carefully managed.

1. Increased Thermal Fatigue

Higher firing temperatures mean greater thermal gradients during startup and shutdown. Over time, this can lead to crack initiation and propagation in metal components, especially in combustors and turbine blades. Regular non-destructive testing (NDT) and borescope inspections are crucial for early detection.

2. Higher NOx Emissions

As combustion temperatures rise, nitrogen oxides (NOx)—harmful pollutants—tend to increase. To counter this, many systems integrate low-NOx combustor designs or selective catalytic reduction (SCR) systems to maintain compliance with environmental regulations.

3. More Frequent Inspections and Overhauls

Operating closer to material limits often shortens maintenance intervals. Hot gas path inspections (HGPIs), major inspections, and borescope evaluations must be conducted more regularly to assess coating integrity, blade wear, and cooling channel cleanliness.

4. Balancing Performance with Reliability

A firing temperature upgrade must be evaluated within the context of the entire plant’s operation. While short-term performance gains are valuable, the long-term impact on lifecycle costs and reliability must be carefully considered.

Best Practices for Implementing Firing Temperature Increases

When planning a performance upgrade involving firing temperature increases, plant operators should work closely with experienced service providers who understand the mechanical, thermal, and operational aspects of the turbine.

Here are key recommendations:

- Perform baseline performance testing before upgrades to quantify improvements.

- Assess the condition of all hot gas path components through detailed inspections.

- Use OEM or equivalent high-grade materials for replacement or refurbishment.

- Incorporate advanced cooling and coating solutions tailored to the turbine model.

- Develop a predictive maintenance plan to monitor component health post-upgrade.

- Verify emissions compliance after any combustion or firing temperature changes.

Companies like Allied Power Group specialize in providing these integrated solutions—combining engineering expertise, component repair, and performance analytics to ensure that every degree of temperature increase translates into reliable, efficient power generation.

Conclusion

Increasing the firing temperature is one of the most effective ways to boost gas turbine performance, but it’s not as simple as turning up the heat. It requires a deep understanding of material science, cooling systems, and combustion dynamics.

Through advanced coatings, precision cooling, and expert maintenance of hot gas path components, operators can safely push performance limits while maintaining reliability and regulatory compliance.

With the right partner—such as Allied Power Group—industrial operators can implement firing temperature increases that deliver measurable performance improvements, longer component life, and higher overall plant efficiency.